HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO Kamfanin Sin na Sin na Cryogenic Oxygen Plant Don Narke Karfe Mai Tsabta Tsabta 99.6% Na'urar Karafa ta Iskar Oxygen

Bayani dalla-dalla:

| Sunan Samfuri | Kayan aikin rabuwar iska mai ban tsoro |

| Lambar Samfura | NZDON- 50/60/80/100/120AN KEƁANCE |

| Alamar kasuwanci | NuZhuo |

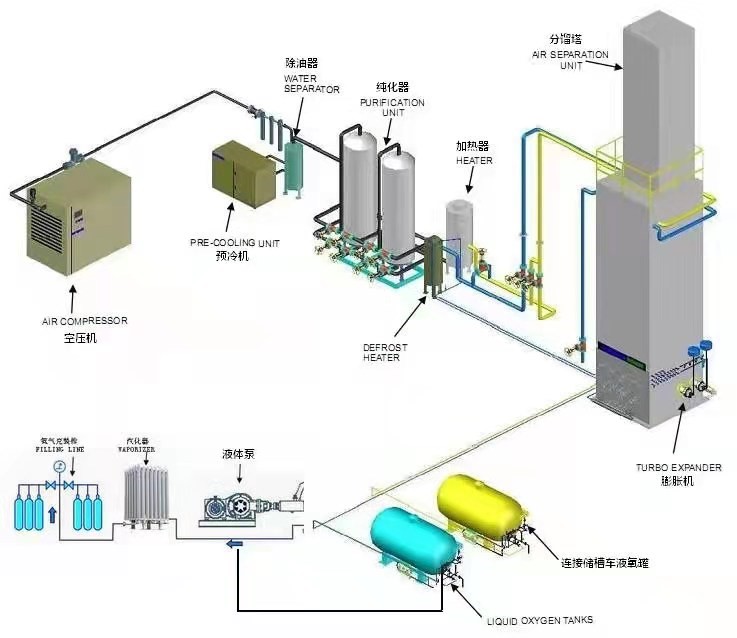

| Kayan haɗi | Tsarin sanyaya iska & Tsarin Faɗaɗawa & Akwatin Sanyi |

| Amfani | Injin samar da iskar oxygen da nitrogen da argon mai tsarki |

Tsarin samar da iskar oxygen mai ƙarfi da kuma samar da iskar oxygen da nitrogen yana gabatar da tsarin rage matsin lamba a cikin kayan aikin raba iska, wanda ke rage yawan amfani da makamashin raba iska da kuma inganta tsaron aiki. Ana amfani da manhajojin sinadarai masu dacewa wajen ƙididdigewa da ƙira kayan aiki na naúra don ƙididdige na'urorin raba iska da kuma ƙididdigewa don tabbatar da kayan aiki masu inganci da inganci.

Domin biyan buƙatun kasuwa, baya ga samar da kayan aikin raba iska na waje na yau da kullun, kamfanin ya kuma ƙirƙiro jerin hanyoyin raba iska na ciki, wanda ke rage nauyin shigarwa da kula da kayan aiki na cikakken saitin kayan aiki.

Kamfanin ya tsara kuma ya ƙirƙiro tsarin tsarkakewa mai hawa siminti don rage lokacin shigar da bututu a wurin.

| Samfuri | NZDON-50/50 | NZDON-80/160 | NZDON-180/300 | NZDON-260/500 | NZDON-350/700 | NZDON-550/1000 | NZDON-750/1500 | NZDON-1200/2000/0y |

| Fitowar O2 0 (Nm3/h) | 50 | 80 | 180 | 260 | 350 | 550 | 750 | 1200 |

| Tsarkakakken O2 (%O2) | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 |

| Fitar N2 0 (Nm3/h) | 50 | 160 | 300 | 500 | 700 | 1000 | 1500 | 2000 |

| Tsarkakakken N2 (PPm O2) | 9.5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Ruwan Argon na Ruwa (Nm3/h) | —— | —— | —— | —— | —— | —— | —— | 30 |

| Tsarkakakken Argon Mai Ruwa (Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | ≤1.5ppmO2 + 4ppm mN2 |

| Tsarkakakken Argon Mai Ruwa (Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | 0.2 |

| Amfani (Kwh/Nm3 O2) | ≤1.3 | ≤0.85 | ≤0.68 | ≤0.68 | ≤0.65 | ≤0.65 | ≤0.63 | ≤0.55 |

| Yankin da aka mamaye (m3) | 145 | 150 | 160 | 180 | 250 | 420 | 450 | 800 |

Matsayin fasahar cryogenic a cikin narkewar ƙarfe:

Babban amfani da iskar oxygen a masana'antu shine tallafin konewa. Yawancin kayan da ba a saba amfani da su a iska ba na iya ƙonewa a cikin iska, don haka haɗa iskar oxygen da iska yana inganta ingancin konewa a masana'antar ƙarfe, waɗanda ba ƙarfe ba, gilashi da siminti. Idan aka haɗa shi da iskar gas, ana amfani da shi sosai a yanka, walda, brazing da busa gilashi, yana samar da zafi mafi girma fiye da konewar iska, don haka yana inganta inganci. Tare da tsarin oxyfuel, plasma da laser, ana iya amfani da jiragen iskar gas don yanke ƙarfe. Hakanan ana amfani da iskar oxygen don haƙa kayan haɗin zafi ko yankewa kamar siminti, tubali, dutse da ƙarfe daban-daban.

Bayanin Kamfani

Takardar Shaida & NUZHUO

Q1: Shin kai kamfani ne na kasuwanci ko masana'anta?

Q3: Har yaushe ne lokacin isar da kayanku?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

T4: Menene manufar tabbatar da ingancin samfur ɗinku?

Q5: Shin kuna bayar da sabis na OEM/ODM?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comT6: Shin samfurinka ya yi amfani ko sabo? Samfurin RTS ko samfurin da aka keɓance?

Nau'ikan Samfura

Mayar da hankali kan samar da mafita na mong pu na tsawon shekaru 5.

Waya: 0086-15531448603

Waya: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com