Sashen raba iska na KDON-32000/19000 shine babban sashin injiniyan jama'a da ke tallafawa aikin ethylene glycol t/a 200,000. Ya fi samar da hydrogen mai ɗanɗano ga sashin gasification mai matsin lamba, sashin hada ethylene glycol, dawo da sulfur, da kuma maganin najasa, kuma yana samar da nitrogen mai ƙarfi da ƙarancin matsin lamba ga sassa daban-daban na aikin ethylene glycol don tsaftacewa da rufewa, sannan kuma yana samar da iska da iska ta naúrar.

A. Tsarin Fasaha

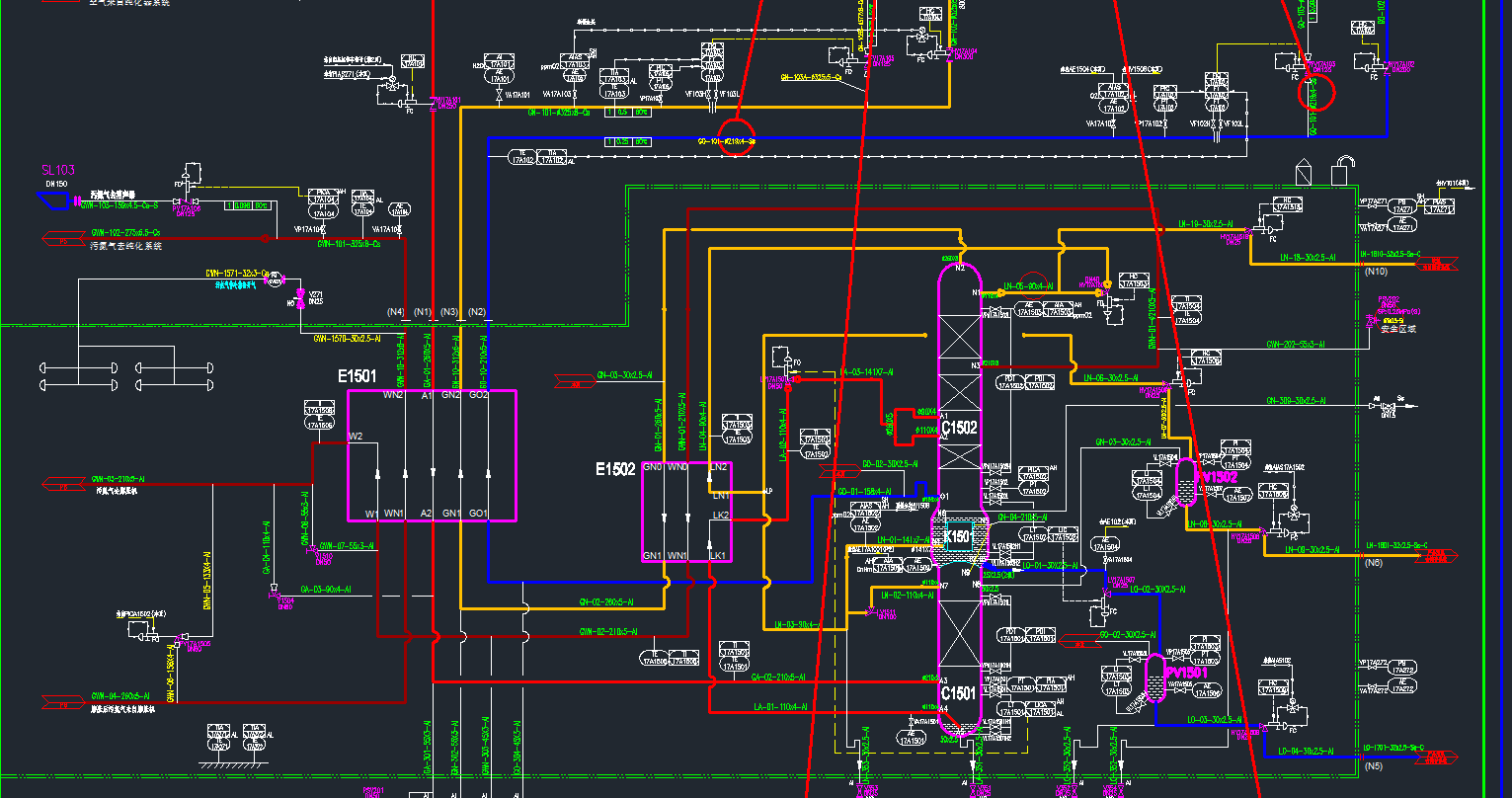

Kayan aikin raba iska na KDON32000/19000 Newdraft ne ya tsara kuma ya ƙera su, kuma ya rungumi tsarin kwararar aiki na tsarkakewar ƙwayoyin halitta mai ƙarancin matsin lamba, injin faɗaɗa turbine mai ƙarfafa iska, matsi na ciki na iskar oxygen, matsi na waje na nitrogen mai ƙarancin matsin lamba, da kuma zagayawa ta iska mai ƙarfafa iska. Hasumiyar ƙasa ta ɗauki hasumiyar farantin sieve mai inganci, kuma hasumiyar sama ta ɗauki tsarin tattarawa da kuma cikakken distillation na argon mara hydrogen.

Ana tsotse iskar da ba ta da amfani daga shiga, kuma ana cire ƙura da sauran ƙazanta ta hanyar matatar iska mai tsaftace kanta. Iskar bayan matatar ta shiga cikin mashin ɗin centrifugal, kuma bayan mashin ɗin ya matse ta, tana shiga hasumiyar sanyaya iska. Yayin sanyaya, tana iya tsaftace ƙazanta waɗanda suke narkewa cikin sauƙi a cikin ruwa. Iskar bayan ta bar hasumiyar sanyaya tana shiga cikin mashin ɗin sieve na ƙwayoyin halitta don canzawa. Ana shaye carbon dioxide, acetylene da danshi a cikin iska. Ana amfani da mashin ɗin sieve na ƙwayoyin halitta a cikin yanayi biyu na sauyawa, ɗaya daga cikinsu yana aiki yayin da ɗayan kuma yana sake farfadowa. Zagayen aikin mai tsarkakewa yana kimanin awanni 8, kuma ana canza mashin ɗin sieve sau ɗaya a kowace awa 4, kuma ana sarrafa mashin ɗin sieve ta atomatik ta hanyar shirin da za a iya gyarawa.

Iskar bayan an haɗa sieve na ƙwayoyin halitta zuwa rafuka uku: ana fitar da rafi kai tsaye daga sieve na ƙwayoyin halitta a matsayin iskar kayan aiki don kayan aikin rabuwar iska, rafi ɗaya yana shiga cikin mai musayar zafi mai ƙarancin matsin lamba, ammonia da ammonia da suka gurɓata ta hanyar reflux, sannan ya shiga hasumiyar ƙasa, rafi ɗaya yana zuwa ga mai haɓaka iska, kuma an raba shi zuwa rafuka biyu bayan matse matakin farko na mai haɓaka. Ana cire rafi ɗaya kai tsaye kuma ana amfani da shi azaman iska da iska na kayan aikin tsarin bayan an rage matsin lamba, ɗayan kuma yana ci gaba da matsa lamba a cikin mai haɓaka kuma an raba shi zuwa rafuka biyu bayan an matse shi a mataki na biyu. Ana cire rafi ɗaya kuma a sanyaya shi zuwa zafin ɗaki kuma yana zuwa ƙarshen mai haɓaka sieve na mai haɓaka turbine don ƙarin matsa lamba, sannan ana cire shi ta hanyar mai musayar zafi mai matsin lamba kuma yana shiga mai faɗaɗa don faɗaɗawa da aiki. Iska mai laushi da aka faɗaɗa tana shiga mai raba gas-ruwa, kuma iskar da aka raba ta shiga hasumiyar ƙasa. Iskar ruwa da aka cire daga mai raba iskar gas tana shiga hasumiyar ƙasa a matsayin ruwan iskar gas, kuma ɗayan rafin yana ci gaba da matsawa a cikin mai haɓaka har zuwa matakin ƙarshe na matsewa, sannan mai sanyaya ya sanyaya zuwa zafin ɗaki sannan ya shiga mai musayar zafi mai ƙarfi na farantin fila don musayar zafi tare da iskar oxygen mai ruwa da kuma gurɓataccen nitrogen mai reflux. Ana zuba wannan ɓangaren iskar mai ƙarfi a cikinsa Bayan an cire iskar ruwa daga ƙasan mai musayar zafi, yana shiga hasumiyar ƙasa bayan matsewa. Bayan an fara tace iskar a cikin hasumiyar ƙasa, ana samun iskar ruwa mai laushi, iskar ruwa mai wadataccen oxygen, nitrogen mai tsafta da ammonia mai tsafta. Ana sanyaya iskar ruwa mai laushi, iskar ruwa mai wadataccen oxygen da nitrogen mai tsafta a cikin mai sanyaya kuma ana matse ta cikin hasumiyar sama don ƙarin matsewa. Ana matse iskar oxygen da aka samu a ƙasan hasumiyar sama ta famfon oxygen na ruwa sannan a shiga mai musayar zafi mai ƙarfi na farantin fila don sake dumamawa, sannan a shiga hanyar sadarwa ta bututun iskar oxygen. Ana cire nitrogen mai ruwa da aka samu a saman hasumiyar ƙasa kuma yana shiga tankin ajiyar ammonia mai ruwa. Ana sake dumama sinadarin ammonia mai tsaftar da aka samu a saman hasumiyar ƙasa ta hanyar na'urar musayar zafi mai ƙarancin matsin lamba kuma tana shiga hanyar sadarwa ta bututun ammonia. Ana sake dumama sinadarin nitrogen mai ƙarancin matsin lamba da aka samu daga saman hasumiyar sama ta hanyar na'urar musayar zafi mai ƙarancin matsin lamba sannan ta fita daga akwatin sanyi, sannan a matse shi zuwa 0.45MPa ta hanyar na'urar kwampreso ta nitrogen sannan ta shiga hanyar sadarwa ta bututun ammonia. Ana cire wani adadin ɓangaren argon daga tsakiyar hasumiyar sama sannan a aika shi zuwa hasumiyar xenon mai ɗanɗano. Ana tace ɓangaren xenon a cikin hasumiyar argon mai ɗanɗano don samun argon mai ɗanɗano, wanda daga nan ake aika shi zuwa tsakiyar hasumiyar argon mai tsafta. Bayan an tace shi a cikin hasumiyar argon mai tsafta, ana samun xenon mai tsafta a ƙasan hasumiyar. Ana fitar da iskar gas ta ammonia daga saman hasumiyar sama, kuma bayan an sake dumama ta ta hanyar mai sanyaya, mai ƙarancin matsin lamba da mai musayar zafi na farantin filafilin mai ƙarfi sannan ya fita daga akwatin sanyi, sai ya raba zuwa sassa biyu: ɓangare ɗaya yana shiga cikin hita tururi na tsarin tsarkake sieve na kwayoyin halitta a matsayin iskar sake farfaɗo da sieve na kwayoyin halitta, kuma sauran iskar nitrogen mai datti yana zuwa hasumiyar sanyaya ruwa. Lokacin da ake buƙatar fara tsarin madadin iskar oxygen na ruwa, ana canza iskar oxygen na ruwa a cikin tankin ajiyar iskar oxygen na ruwa zuwa mai tururi na iskar oxygen ta hanyar bawul mai daidaitawa, sannan ya shiga hanyar sadarwa ta bututun oxygen bayan samun iskar oxygen mai ƙarancin matsin lamba; lokacin da ake buƙatar fara tsarin madadin nitrogen na ruwa, ana canza ammonia na ruwa a cikin tankin ajiyar nitrogen na ruwa zuwa mai tururi na iskar oxygen ta hanyar bawul mai daidaitawa, sannan a matse ta da matsewar ammonia don samun nitrogen mai matsin lamba da ammonia mai ƙarancin matsin lamba, sannan a shiga hanyar sadarwa ta bututun nitrogen.

B.TSARIN SAKO

Dangane da girman da halayen aikin kayan aikin raba iska, an karɓi tsarin sarrafawa na DCS da aka rarraba, tare da zaɓar tsarin DCS na duniya, masu nazarin bawul ɗin sarrafawa ta yanar gizo da sauran sassan aunawa da sarrafawa. Baya ga iya kammala sarrafa tsarin naúrar raba iska, yana iya sanya duk bawul ɗin sarrafawa a cikin aminci lokacin da aka rufe naúrar a cikin haɗari, kuma famfunan da suka dace suna shiga yanayin kullewa na aminci don tabbatar da amincin naúrar raba iska. Manyan na'urorin kwampreso na turbine suna amfani da tsarin sarrafawa na ITCC (tsarin sarrafawa na naúrar kwampreso mai haɗaka) don kammala sarrafa tafiya mai sauri na naúrar, sarrafa yankewa na gaggawa da ayyukan sarrafa hana hauhawar ruwa, kuma suna iya aika sigina zuwa tsarin sarrafawa na DCS a cikin nau'in wayoyi masu ƙarfi da sadarwa.

C. Babban wuraren sa ido na na'urar raba iska

Binciken tsarki na iskar oxygen da iskar nitrogen da ke barin na'urar musayar zafi mai ƙarancin matsin lamba, nazarin tsarki na iskar ruwa ta ƙasan hasumiya, nazarin tsantsar nitrogen mai tsafta na hasumiya, nazarin tsarki na iskar gas da ke barin hasumiya ta sama, nazarin tsarki na iskar gas da ke shiga ƙarƙashin sanyaya, nazarin tsarki na iskar oxygen a cikin hasumiya ta sama, zafin jiki bayan ɗanyen mai na'urar reflux mai narkewar iskar ruwa mai ɗorewa, matsi da matakin ruwa na nunin mai raba gas da ruwa na hasumiya mai distillation, nunin zafin jiki na iskar nitrogen da datti da ke barin mai musayar zafi mai matsin lamba, nazarin tsarki na iska da ke shiga mai musayar zafi mai ƙarancin matsin lamba, zafin jiki na iska da ke barin mai musayar zafi mai matsin lamba, bambancin zafin jiki da zafin jiki na iskar ammonia da datti da ke barin mai musayar zafi, nazarin iskar gas a tashar cire xenon ta sama: duk waɗannan don tattara bayanai ne yayin farawa da aiki na yau da kullun, wanda ke da amfani don daidaita yanayin aiki na na'urar raba iska da tabbatar da aikin yau da kullun na kayan aikin raba iska. Binciken sinadarin nitrous oxide da acetylene a cikin babban sanyaya, da kuma nazarin sinadarin danshi a cikin iska mai ƙarfi: Domin hana iska mai danshi shiga tsarin distillation, yana haifar da tauri da toshe hanyar musayar zafi, yana shafar yankin musayar zafi da inganci, acetylene zai fashe bayan tarin a cikin babban sanyaya ya wuce wani ƙima. Hatimin shaft na famfon iskar oxygen mai ruwa, nazarin matsin lamba, zafin zafi na famfon iskar oxygen mai ruwa, zafin iskar gas mai labyrinth, zafin iskar ruwa bayan faɗaɗawa, matsin iskar gas mai faɗaɗawa, kwarara, nunin matsin lamba daban-daban, matsi mai mai mai, matakin tankin mai da mai sanyaya zafin baya, ƙarshen faɗaɗa mai mai faɗaɗawa, kwararar mai mai ƙara ƙarfi, zafin jiki mai ɗaukar nauyi, nunin girgiza: duk don tabbatar da aiki lafiya da al'ada na mai faɗaɗa mai da famfon iskar oxygen mai ruwa, kuma a ƙarshe don tabbatar da aikin rarraba iska yadda ya kamata.

Babban matsin lamba na dumama sieve na ƙwayoyin halitta, nazarin kwararar ruwa, yanayin shigar iskar sieve na ƙwayoyin halitta (dattin nitrogen) da zafin fita, nunin matsin lamba, zafin iskar sieve na ƙwayoyin halitta da kwararar ruwa, nunin juriyar tsarin tsarkakewa, nunin bambancin matsin lamba na sieve na ƙwayoyin halitta, zafin shigar tururi, ƙararrawa ta nuna matsin lamba, ƙararrawa ta nazarin iskar gas ta sake farfadowa ƙararrawa ta nazarin H20, ƙararrawa ta zafin fitarwa na condensate, nazarin sieve na ƙwayoyin halitta na iska CO2, hasumiyar ƙasa ta shigar iska da nunin kwararar mai ƙarfafawa: don tabbatar da cewa tsarin shaƙar sieve na ƙwayoyin halitta na yau da kullun da kuma tabbatar da cewa abubuwan da ke cikin iskar CO2 da H20 na iska da ke shiga akwatin sanyi suna cikin ƙaramin matakin. Alamar matsin lamba ta kayan aiki: don tabbatar da cewa iskar kayan aiki don rabuwar iska da iskar kayan aiki da aka bayar zuwa hanyar sadarwa ta bututun mai sun kai 0.6MPa (G) don tabbatar da aikin samarwa na yau da kullun.

D. Halayen na'urar raba iska

1. Halayen tsari

Saboda matsin lamba mai yawa na aikin ethylene glycol, kayan aikin rabuwar iska na KDON32000/19000 sun rungumi zagayowar haɓaka iska, matsi na ciki na iskar oxygen da kuma tsarin matsi na waje na ammonia, wato, an haɗa mai faɗaɗa iska + famfon iskar oxygen mai ruwa + mai ƙarfafa turbine tare da tsarin musayar zafi mai ma'ana don maye gurbin mai matsa iskar oxygen mai aiki da matsin lamba na waje. Haɗarin aminci da amfani da masu matsa iskar oxygen ke haifarwa a cikin tsarin matsi na waje yana raguwa. A lokaci guda, yawan iskar oxygen mai ruwa da babban sanyaya ke fitarwa na iya tabbatar da cewa an rage yiwuwar tara hydrocarbon a cikin babban iskar oxygen mai sanyaya don tabbatar da ingantaccen aikin kayan aikin rabuwar iska. Tsarin matsi na ciki yana da ƙananan farashin saka hannun jari da kuma tsari mai ma'ana.

2. Halayen kayan aikin raba iska

Matatar iska mai tsaftace kanta tana da tsarin sarrafawa ta atomatik, wanda zai iya juyawa ta atomatik kuma zai iya daidaita shirin bisa ga girman juriya. Tsarin sanyaya iska yana ɗaukar hasumiyar tattarawa mai inganci da ƙarancin juriya, kuma mai rarraba ruwa yana ɗaukar sabon mai rarrabawa mai inganci, wanda ba wai kawai yana tabbatar da cikakken hulɗa tsakanin ruwa da iska ba, har ma yana tabbatar da aikin musayar zafi. An sanya na'urar cire waya a saman don tabbatar da cewa iskar da ke fitowa daga hasumiyar sanyaya iska ba ta ɗauke da ruwa. Tsarin shaƙar sieve na ƙwayoyin halitta yana ɗaukar dogon zango da tsarkake gado mai layuka biyu. Tsarin sauyawa yana ɗaukar fasahar sarrafa sauyawa ba tare da tasiri ba, kuma ana amfani da hita na tururi na musamman don hana tururin dumama ya zube zuwa ɓangaren nitrogen mai datti yayin matakin sake farfaɗowa.

Duk tsarin tsarin hasumiyar distillation ya rungumi lissafin kwaikwayon manhajar ASPEN da HYSYS na duniya. Hasumiyar ƙasa ta ɗauki hasumiyar farantin sieve mai inganci kuma hasumiyar sama ta ɗauki hasumiyar marufi ta yau da kullun don tabbatar da yawan fitar da na'urar da rage yawan amfani da makamashi.

E. Tattaunawa kan tsarin sauke da loda motocin da ke amfani da na'urar sanyaya daki

1. Sharuɗɗan da ya kamata a cika kafin a fara raba iska:

Kafin fara aiki, shirya kuma rubuta tsarin fara aiki, gami da tsarin fara aiki da kuma kula da hatsarin gaggawa, da sauransu. Duk ayyukan da ake gudanarwa a lokacin fara aiki dole ne a yi su a wurin.

An kammala aikin tsaftacewa, wankewa da kuma gwada tsarin mai mai shafawa. Kafin fara amfani da famfon mai mai shafawa, dole ne a ƙara iskar gas mai rufewa don hana zubewar mai. Da farko, dole ne a gudanar da tace mai mai da ke zagayawa a cikin tankin mai mai shafawa. Idan aka isa wani matakin tsafta, ana haɗa bututun mai don wankewa da tacewa, amma ana ƙara takardar tacewa kafin shiga cikin matsewa da injin turbine kuma ana ci gaba da maye gurbinsa don tabbatar da tsaftar mai da ke shiga cikin kayan aiki. Ana kammala wankewa da aiwatar da tsarin ruwa mai zagayawa, tsarin tsaftace ruwa, da tsarin magudanar ruwa na rabuwar iska. Kafin shigarwa, ana buƙatar a cire mai, a tace, sannan a cika bututun mai mai da iskar oxygen na rabuwar iska, sannan a cika shi da iskar gas mai rufewa. An sanya bututun mai, injina, lantarki, da kayan aiki (banda kayan aikin nazari da kayan aikin aunawa) na kayan aikin rabuwar iska kuma an daidaita su don cancanta.

Duk famfunan ruwa na injina da ke aiki, famfunan iskar oxygen na ruwa, na'urorin sanyaya iska, na'urorin ƙara ƙarfi, na'urorin faɗaɗa turbine, da sauransu suna da sharuɗɗan farawa, kuma ya kamata a fara gwada wasu a kan injin guda ɗaya.

Tsarin canza sieve na kwayoyin halitta yana da yanayin farawa, kuma an tabbatar da cewa shirin canza kwayoyin halitta yana iya aiki yadda ya kamata. An kammala dumama da tsaftace bututun tururi mai matsin lamba mai yawa. An fara amfani da tsarin iska na kayan aiki na jiran aiki, yana kiyaye matsin iska na kayan aiki sama da 0.6MPa(G).

2. Tsaftace bututun raba iska

Fara tsarin mai mai shafawa da tsarin iskar gas na turbin tururin, na'urar kwampreso ta iska da kuma famfon ruwan sanyaya. Kafin fara kwampreso ta iska, buɗe bawul ɗin iska na na'urar kwampreso ta iska sannan a rufe hanyar shiga iska ta hasumiyar sanyaya iska da faranti mai rufewa. Bayan an tsaftace bututun fitar da iska, matsin lamba na shaye-shaye ya kai matsin lamba na shaye-shaye kuma an daidaita manufar tsaftace bututun, a haɗa bututun shigar da iska a cikin hasumiyar sanyaya iska, a fara tsarin sanyaya iska (kafin a tsaftace, ba za a cika marufin hasumiyar sanyaya iska ba; an cire flange ɗin shigar da iska a cikin sieve), a jira har sai an cancantar abin da ake so, a fara tsarin tsarkake sieve na kwayoyin halitta (kafin a wanke, ba za a cika mai karɓar sieve na kwayoyin halitta ba; dole ne a cire flange ɗin shigar da iska a cikin akwatin sanyi), a dakatar da mai karɓar iska har sai an cancantar abin da ake so, a cika marufin hasumiyar sanyaya iska da mai karɓar sieve na kwayoyin halitta, sannan a sake kunna matattarar, turbine mai tururi, mai karɓar iska, tsarin sanyaya iska, tsarin shaye-shaye na kwayoyin halitta bayan an cika, aƙalla makonni biyu na aiki na yau da kullun bayan sake farfaɗowa, sanyaya, ƙaruwar matsi, shaye-shaye, da rage matsi. Bayan wani lokaci na dumama, ana iya hura bututun iska na tsarin bayan mai karɓar sieve na kwayoyin halitta da bututun ciki na hasumiyar rabawa. Wannan ya haɗa da na'urorin musanya zafi mai ƙarfi, na'urorin musanya zafi mai ƙarancin matsin lamba, na'urorin haɓaka iska, na'urorin faɗaɗa turbine, da kayan aikin hasumiya waɗanda suka haɗa da rabuwar iska. Kula da sarrafa kwararar iska da ke shiga tsarin tsarkake sieve na kwayoyin halitta don guje wa juriyar sieve na kwayoyin halitta da ke lalata layin gado. Kafin a hura hasumiyar rarrabawa, dole ne a sanya duk bututun iska da ke shiga akwatin sanyi na hasumiyar rarrabuwar abubuwa na wucin gadi don hana ƙura, walda da sauran ƙazanta shiga mai musayar zafi da kuma shafar tasirin musayar zafi. Fara tsarin mai mai shafawa da iskar gas kafin a hura mai faɗaɗa turbine da famfon iskar oxygen na ruwa. Dole ne a rufe duk wuraren rufe iskar gas na kayan aikin raba iska, gami da bututun faɗaɗa turbine.

3. Sanyaya jiki ba tare da an saka shi ba da kuma ƙaddamar da na'urar raba iska ta ƙarshe

Ana hura dukkan bututun da ke wajen akwatin sanyi, kuma dukkan bututun da kayan aiki da ke cikin akwatin sanyi ana dumama su kuma ana hura su don dacewa da yanayin sanyaya da kuma shirya gwajin sanyaya mara komai.

Lokacin da sanyaya hasumiyar distillation ta fara, iskar da na'urar damfara ta iska ke fitarwa ba za ta iya shiga hasumiyar distillation gaba ɗaya ba. Iskar da aka matse ta wuce gona da iri tana fitar da iskar da ta wuce gona da iri zuwa sararin samaniya ta hanyar bawul ɗin iska, ta haka ne za ta sa matsin lamba na fitar da na'urar damfara ta iska ba ya canzawa. Yayin da zafin kowane ɓangare na hasumiyar distillation ke raguwa a hankali, adadin iskar da aka shaƙa zai ƙaru a hankali. A wannan lokacin, ana aika wani ɓangare na iskar reflux da ke cikin hasumiyar distillation zuwa hasumiyar sanyaya ruwa. Ya kamata a gudanar da aikin sanyaya a hankali da daidaito, tare da matsakaicin saurin sanyaya na 1 ~ 2℃/h don tabbatar da yanayin zafi iri ɗaya na kowane ɓangare. A lokacin aikin sanyaya, ya kamata a kiyaye ƙarfin sanyaya na na'urar faɗaɗa iskar gas a matsakaicin matsayi. Lokacin da iskar da ke ƙarshen sanyi na babban mai musayar zafi ta kusa da zafin ruwa, matakin sanyaya zai ƙare.

Ana kiyaye matakin sanyaya akwatin sanyi na wani lokaci, kuma ana duba da gyara ɓuɓɓuga daban-daban da sauran sassan da ba a kammala ba. Sannan a dakatar da injin mataki-mataki, a fara ɗora yashi lu'u-lu'u a cikin akwatin sanyi, a fara kayan aikin raba iska mataki-mataki bayan lodawa, sannan a sake shiga matakin sanyaya. Lura cewa lokacin da aka fara kayan aikin raba iska, iskar sake farfaɗowa ta sieve ta kwayoyin halitta tana amfani da iskar da sieve ta kwayoyin halitta ta tsarkake. Lokacin da aka fara kayan aikin raba iska kuma akwai isasshen iskar sake farfaɗowa, ana amfani da hanyar kwararar ammonia mai datti. A lokacin aikin sanyaya, zafin jiki a cikin akwatin sanyi yana raguwa a hankali. Ya kamata a buɗe tsarin cike ammonia na akwatin sanyi akan lokaci don hana matsin lamba mara kyau a cikin akwatin sanyi. Sannan kayan aikin da ke cikin akwatin sanyi suna ƙara sanyaya, iskar ta fara sha, ruwa ya fara bayyana a cikin hasumiyar ƙasa, kuma tsarin tacewa na hasumiyoyin sama da ƙasa ya fara kafuwa. Sannan a hankali a daidaita bawuloli ɗaya bayan ɗaya don sa rabuwar iska ta yi aiki yadda ya kamata.

Idan kana son ƙarin bayani, da fatan za a tuntuɓe mu cikin yardar kaina:

Mai hulɗa: Lyan.Ji

Lambar waya: 008618069835230

Mail: Lyan.ji@hznuzhuo.com

Whatsapp: 008618069835230

WeChat: 008618069835230

Lokacin Saƙo: Afrilu-24-2025

Waya: 0086-15531448603

Waya: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com